Dimethyl Silicone Oil 201

- CAS number: 63148-62-9

- Chemical formula: (C2H6OSi)n

- Brand: Pacific Silicone

- Origin: Vietnam

- Packaging: Packed in plastic containers, steel drums

- Weight: 1000 kg, 200 kg

- Storage: 24 months from the date of manufacture

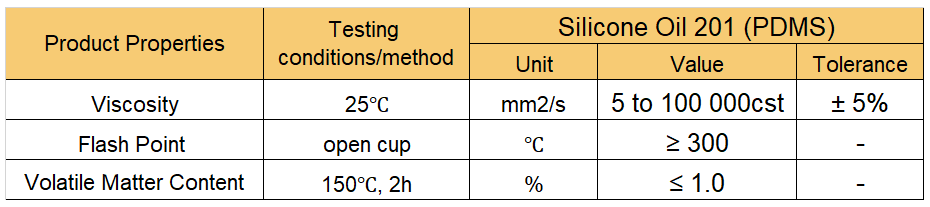

Technical specifications

Application

- Used in factories producing silicone rubber products, silicone adhesives...

- Used in the textile and leather industry: Softening agents, smoothers in the finishing process of fabrics and leather, lubricants for sewing threads, machinery...

- Used to formulate lubricating oil, anti-vibration oil, thermal insulation oil, defoaming agents, film stripping agents….

- Used in the production of polishing additives: Used in the automotive, interior, and metal industries in the form of paste, emulsion...